The Japanese tool “5S”

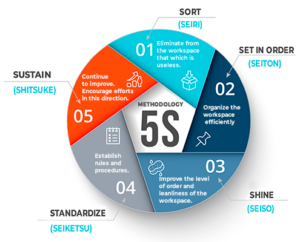

The Japanese tool “5S” is structured in the steps of Sort, Set in Order, Shine, Standardize and Sustain. The objectives associated with this philosophy are the reduction of incidents and risks, pleasant and comfortable environments and improvement in product quality, to mention a few.

Every year, audits are carried out at the different plants to verify compliance with this philosophy. Thanks to the changes implemented within the “5S”, we have achieved noticeable results in our facilities, evidencing continuous improvement.